Process Innovation

Conventional antenna production consumes a lot of power and can easily produce pollution, especially during the electroplating and soldering processes.

In Electroplating, while essential for many industries, is a major source of environmental pollution. It contributes to water pollution through the release of heavy metal ions, cyanide, acids, and organic compounds. Additionally, it releases air pollutants like acid mists and dust, and generates solid waste, primarily sludge containing heavy metals and cyanide

The soldering process in antenna manufacturing contributes to air pollution by releasing heavy metals such as tin and lead, as well as other harmful substances like rosin and acid dust. Moreover, the reliance on manual soldering techniques using soldering irons results in low production efficiency and increased labor costly.

For these reasons, the innovation objectives of antenna manufacturing process should focus on the elimination of electroplating and soldering, as well as the reduction of power consumption and manual operation. Given the significant environmental and efficiency challenges associated with electroplating and soldering processes, innovative approaches are needed to reduce their reliance. Laser welding emerges as a promising alternative to traditional soldering, offering several advantages:

Laser Welding

Process innovation and architectural design are closely intertwined. New processes can only be implemented with appropriate architectural designs, while innovative architectural concepts often require the development of new processes. A successful process innovation strategy involves a comprehensive approach that encompasses product design, equipment upgrades, workforce training, and industry-wide collaboration to achieve end-to-end technological advancements

- Electroplating of soldering parts is not required, which directly reduces the pollution and power

- Laser welding directly melts and connects the contact parts of two components. No medium such as tin is required, and therefore no smoke or dust pollution is generated.

- The spatial characteristics of lasers allow for precision soldering, making laser welding an ideal choice for processing of complex antenna components with high precision requirements.

- It can also help facilitate automated manufacturing for higher efficiency.

Form Innovation - One Box Solution

Antennas, often installed on top of structures with limited space, require simplified designs and enhanced configuration capabilities to accommodate efficient network construction and future upgrades.

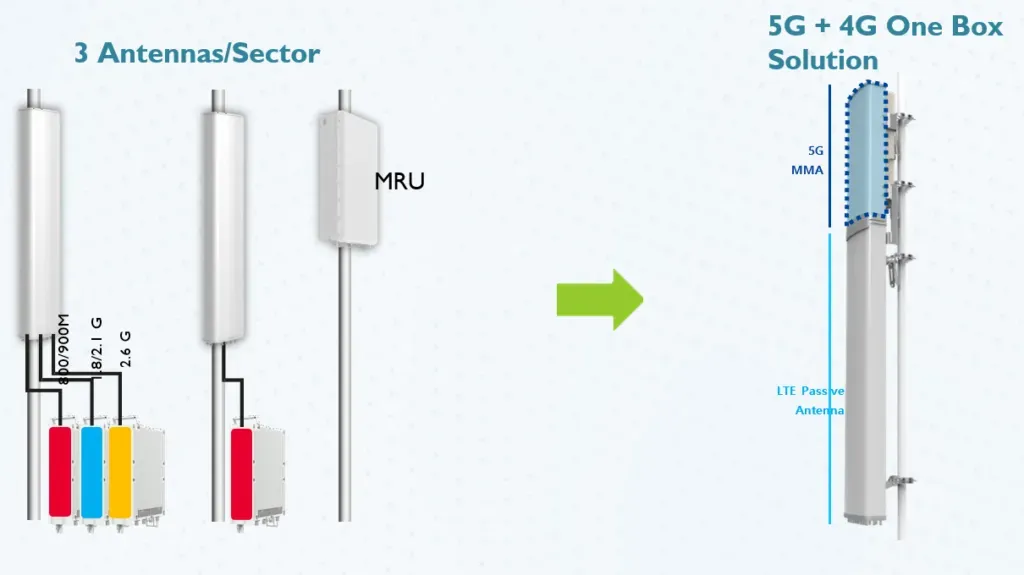

Integrate On-Tower Equipment to Reduce the Number of Boxes:

The increasing availability of spectrum resources has led to a proliferation of antennas and RF units on cell sites. To address this challenge, antenna configurations must evolve to support multiple frequency bands, thereby reducing the number of antennas required per site. While significant advancements have been made in antenna technology, challenges remain, particularly in deploying Massive MIMO antennas on high-frequency bands and passive antennas on low- and mid-frequency bands, which may still require multiple boxes on sites.

In high-capacity scenarios, the deployment of three FDD low-band, three FDD mid-band, and two TDD band Massive MIMO systems by 2025 could require up to eight separate units per sector. This would significantly increase the load on cell sites and may necessitate the construction of new sites to accommodate the additional equipment’s

Green Antenna Technology Articles

Process Innovation for Green Antenna Production

Process Innovation Conventional antenna production consumes a lot of power and can easily produce pollution,…

Read moreMT’s Green Antenna Design & Development Innovation

Innovation in Architecture & Design of Green Antennas The realization of green antenna manufacturing hinges…

Read moreMT’s Green Manufacturing Innovation

Green Manufacturing at MT The manufacturing process of a product, from raw material extraction to…

Read moreMT Green Technology Advantage

MT’s Green Antenna Advantage The manufacturing process of a product, from raw material extraction to…

Read more